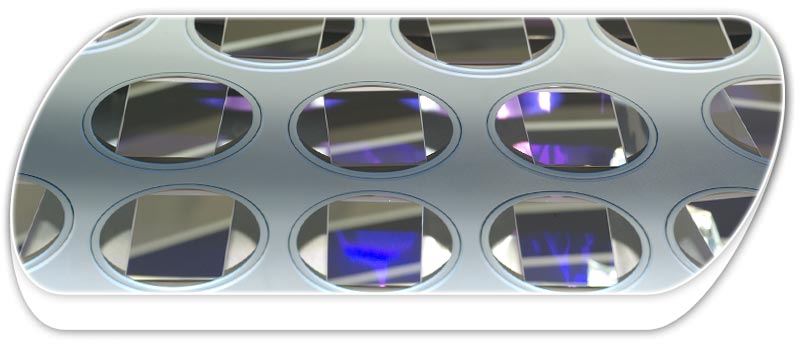

Products

Mirrors/reflectors

The following coatings are available:

- high reflectance laser mirrors for one or more wavelengths

- high reflectance laser mirrors with multiple auxiliary functions

- partially transmitting mirrors

- broadband mirrors with high reflectance

- broadband mirrors with auxiliary functions such as cold light mirrors

- dichroic mirrors

- metallic mirrors of Ag, Al, Au, Cu, Rh, Cr, Ni (unprotected or with dielectric protective overcoat or enhancing dielectric protective overcoat)

- reinforced Ag and Al mirrors with long-term stability by surface hardening using IP technology

- custom mirrors according to customer requirements

Nearly all types of mineral glass and crystal, as well as metal substrates (for metallic coatings) are suitable for coating.

The substrates are usually supplied by the customer.

If required, optical flats with high reflectance coatings can also be offered as complete solution.

![]()

Coatings are deposited using conventional (e-beam) or

ion plating technology, depending on the specifications

Properties

Conventional (e-beam)

- wavelength range 0.24 µm to approx. 2 µm

(metallic mirrors: 0.2 µm to approx. 12 µm) - dielectric mirrors suitable for high laser powers

and large angular ranges of incidence - low stress layers

- also suitable for sensitive substrates

- economical production

Properties

Ion Plating

- wavelength range 0.19 µm to 5 µm

(metallic mirrors: 0.2 µm to 12 µm) - for extremely demanding optical requirements

- suitable for demanding substrate surface flatness specifications

(achieved with compensation coating on rear with any desired optical function. Prerequisites: coplanar substrate, polished on both sides) - extremely low absorption and scatter losses

- gas and water-free coatings for maximum performance, especially in NIR range (e.g. 2.94 µm)

- deposition possible even on highly curved surfaces

- long-term stability of optical and mechanical coating properties regardless of environmental influences (e.g. temperature, pressure, radiation)

- highly resistant to thermal stress (up to 550°C on quartz glass or sapphire)

- suitable for extreme environmental conditions (e.g. space qualified, salt water resistant) and large mechanical stresses (extremely hard and abrasion resistant)